A weblog about pattern, layout and screen printing on textiles. by DALE MCLEOD

A weblog about pattern, layout and screen printing on textiles. by DALE MCLEOD

Repeat printing is best understood as a kind of tiling, because fabrics are generally printed using rollers, which can be seen as large rectangles rolled into a cylinder; tiling also lends it's name to the branch of mathematics known as tessellation.

Fabric printing includes in the larger sense printed T-shirts, as well as the topic of screen printing, which in turn has an elegant interface with computers (both sytems present information on a grid).

The elegance of this branch of design has to be seen in a historical context. Contemporary printed fabric that's at the level of for instance, Victorian wallpaper, is usually only seen in high fashion, or in traditional cultures like Japan.

Today fabric printing is usually done by big companies whose business model apparently doesn't accommodate paying for excellent design--it's the stuff you see in yardage stores, which begins it's journey in the garment industry ('stuff' is an old word for textiles).

There's lot's of beautiful repeat artwork to be seen though, partly because it's a graphic medium that makes good book reproductions, but also because it's most natural manifestation is in tilework, which unlike fabric, lasts for thousands of years.

Stamping a continuous surface using this method is like placing masonry elements--tiles, for example, alongside one another: the edges create a line, which in the case of a brick wall defines the pattern. A tiled surface has two elements: the decoration on the tiles themselves, and the line of mortar.

A brick wall is monotonously repetitive. What's needed is how to interlock the shapes in ways that don't insult the eye: muslim tile designs, for example, beautifully integrate surface motif with the tile edge pattern.

Of course unlike tiles a block print doesn't necessarily have to line up edge-to-edge. The blocks can be moved apart so that there's empty space in between, which then behaves like the masonry grout line, a separate visual element.

photo: Ekabhishek

photo: EkabhishekWhat the woman in the picture is doing is a lot more efficient way to decorate a surface, however, once the individual blocks are separated by intuitive space the idea is bound to emerge, "what if the shapes were different from each other?" The answer is: they'd begin to tell a story.

This is a rollout of an Olmec fabric printing cylinder that's thought to be the oldest evidence of written language in the new world. The image contains three separate abstract elements: the image of the bird, a banderole, a scroll-like ribbon bearing an inscription, and a glyph representing the date, 3 AJAW.

.

This is a rollout of an Olmec fabric printing cylinder that's thought to be the oldest evidence of written language in the new world. The image contains three separate abstract elements: the image of the bird, a banderole, a scroll-like ribbon bearing an inscription, and a glyph representing the date, 3 AJAW.

.

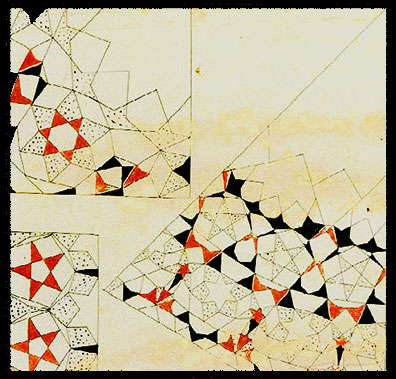

This was the period (shown is the Imam mosque [1611] in Esfahan, Iran) when variations of the arch and the dome were being deployed to span larger & larger spaces. A typical problem faced by Islamic architects was how to embellish a vault, a semi-spherical surface in the corner of a room. The Greeks would have simply inserted a mosaic portrait of a saint, but to cover such a surface with large tiles instead required rigorous design technique. Below is a page from the Topkapi Scroll, a kind of manual for lay

This was the period (shown is the Imam mosque [1611] in Esfahan, Iran) when variations of the arch and the dome were being deployed to span larger & larger spaces. A typical problem faced by Islamic architects was how to embellish a vault, a semi-spherical surface in the corner of a room. The Greeks would have simply inserted a mosaic portrait of a saint, but to cover such a surface with large tiles instead required rigorous design technique. Below is a page from the Topkapi Scroll, a kind of manual for lay  Consider a soccer ball: it's covered with a system of pentagons surrounded by hexagons that together create a spherical surface (this is the same geometric layout as Buckminster Fuller's Geodesic Dome).

Consider a soccer ball: it's covered with a system of pentagons surrounded by hexagons that together create a spherical surface (this is the same geometric layout as Buckminster Fuller's Geodesic Dome).

M C Escher's pictures (above: Shells and Starfish) are better known than his direct influences, which include islamic art as well as Crystallography, the branch of science that deals with the geometric description of crystals and their internal arrangement.

Here's an excellent article on the topic of Islamic tiled geometry. The Tiles of Infinity It's from Aramco World, which was the general interest publication of my dad's company when I was growing up in Saudi Arabia. I came across this piece as part of my research,

Screen printing, also known as silkscreen, or serigraphy, is a method of transfering an image by means of a stencil attached to a porous fabric stretched on a frame: color is pushed through the stencil using a squeegee, a rubber blade with a handle. It's both a commercial technique and an art form.

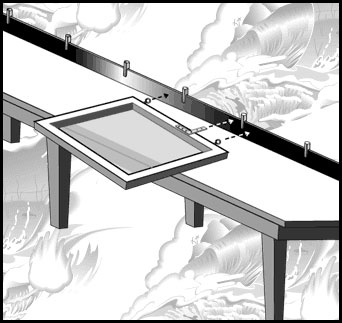

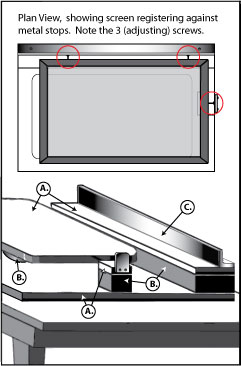

Silkscreened fabric used to be printed flat on long tables like the one pictured above. The important feature is an angle steel rail along one side, which acts as a baseline for aligning the screen along the axis of the fabric; screws driven into one side of the screen contact this surface when printing, and also allow for registration adjustments. The screen is stepped along the length of the fabric by contacting adjustable stops attached to the rail.

A Carousel T-Shirt Printer. The screens rotate into position, pull down, print. This seems intuitively right, however commercial T-shirt printing has evolved around this machine into a mechanized system that makes it difficult to make money without printing runs of hundreds of shirts, limited to roughly a 15" design area. Nevertheless most people who take up T-shirt printing seem to assume that buying large pieces of equipment will drive their business forward .

The advantage of working on a tabletop is it's flexibility. One of my customers was a developer of laser devices--he used what's called an optical bench, a steel table with a grid of threaded holes in the top to set up experiments (in electronics a similar setup is called a "breadboard"). The rail along the edge of the fabric-printing table has the same function as the threaded holes: it's a way to align images in space.

The advantage of working on a tabletop is it's flexibility. One of my customers was a developer of laser devices--he used what's called an optical bench, a steel table with a grid of threaded holes in the top to set up experiments (in electronics a similar setup is called a "breadboard"). The rail along the edge of the fabric-printing table has the same function as the threaded holes: it's a way to align images in space.

A chief advantage of this layout is it's stability: the natural racking tendency, to deform into a parallelogram, of the rectangular screen is countered by the triangle formed by the three contact points. For practical purposes this means that this homemade jig is capable of more precise registration than a basic carousel shirt printing machine. This opens up the interesting possibility of doing something rarely attempted in the industry:four-color (CMYK) printing directly on fabric.

More about this topic:

It's my tripod.com site from 1997. The information still holds up quite well. The printing device pictured above is a direct descendent of the one illustrated there--the newer type needs more practice to load, but it's a lot easier to build.